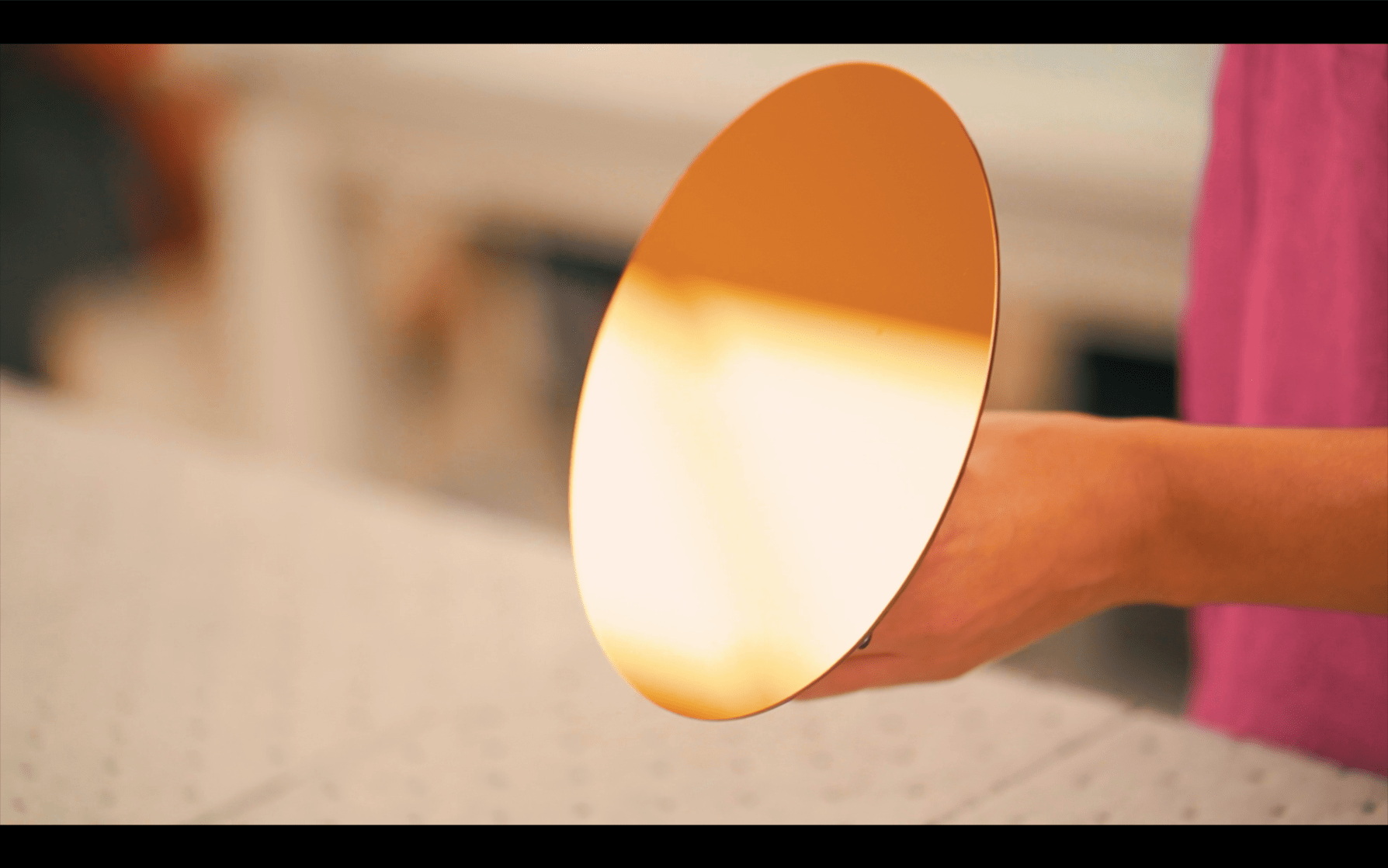

Metal Optics Processing

Metal Optics Processing

Metal Optics Processing

L.A. Gauge’s metal optics polishing capabilities are second to none for prototype and production orders. Using planetary polishing processes and interferometric testing in a controlled environment, our expert opticians achieve superior flatness on a wide variety of geometrical shapes and sizes.

The L.A. Gauge optics laboratory traditionally manufactures metal optic mirrors to demanding flatness tolerances of 1/10 of a wave over a 10-inch diameter face and a surface finish to 20-10.

OPTICAL PROCESSING CENTER

- Two 48-inch Planetary Polishing Machine & One 36-inch Planetary Polishing Machine

- 12” 4D Accufiz Interferometer with 4D Tech Software version 2.8 Rev. A

- 4D Technology Software: 4 sight Interferometer and wave front analysis software Ver. 1.8, Rev. 2

- Davidson 5-inch Fizeau Interferometer

- Wyco 2000 Non-Contact Phase Shift Profilometer

- Master Flat, 1/20 Wave, 6-inch, certified

- Davidson Scratch and Dig standard, certified

- Surface Roughness Standard, 4.6 Angstroms, certified

- Davidson MIL-SPC Viewing Fixture, surface quality.